! LET'S MAKE SOME MOLDS !

With the patterns complete we now move on to making the rubber molds.

I'm using Dow Corning HS II RTV base with the Clay catalyst, which is a very strong and

flexable silastic moldmaking rubber. Since I have already composed an article on mold

making I will direct you there:

Crow's How 2 - Mold Making

The new rubber is very flexable.

Here's a look at some of the new molds I've made. That green

sort of growns on you. After 20 years some of my original 3110 RTV molds are finally

breaking down. Subjecting them to an alchohol wash (de-bubbling agent) didn't help.

I'll be more careful with the new ones. The HS II requires vacumm de-airing in the

process. 3110 does not. The HS II is very stong and flexable.

When complete the patterns are sealed with Scalecoat Sanding Sealer.

The patterns do not have to be glued down to the base but there's a

risk of them shifting out of place and/or breaking.

Here's a series of parts that will all be on the same mold. I've glued

them to the plywood base.

Be sure to fill any openings underneath the patterns with putty, wax

or other.

Petrolum jelly is used as a releasing agent on the patterns and boards.

Simple dams are built with stripwood. I'm leaving a 1/2" wide boarder

around each piece and about 3/16" of thickness.

I'm using Dow Corning's HS II silicone rubber for these molds.

It's softer and more flexable than the 3110 I've normally used. The HS II requires

more careful measurement and vacuum de-airing which the 3110 does not (though its

recommended). We'll see how it goes. Of course there are a number of choices and

brands. This is just what I use for Hydrocal casting.

HS II RTV rubber base and Clay Catalyst.

One scoup of rubber base is about 100 grams.

The rubber and catalyst is carefully weighed out for the 10:1 ratio.

Once mixed the HS II rubber is vacuum de-aired to eliminate bubbles.

The rubber is poured into the mold box.

Just a little more.

The mold box is vigorously tapped to help any trapped air bubbles

rise to the surface.

In order to get a perfectly smooth back on the new mold a sheet of

styrene is placed over the rubber and then a flat board followed with some weight.

I'm using a drill press vise for this.

In the morning a stack of molds for the Durango rounhouse are ready

to have the patterns removed.

Here's that sheet of styrene being removed.

We have a nice flat back.

The excess rubber is trimmed off.

The new mold is gently pulled away from the pattern.

Being careful not to damage the pattern.

Almost have it.

Now we can reproduce those parts.

On some larger pieces I do not glue them to the board. Some rubber

may migrate underneath the pattern. Before removing the pattern from the new mold

the excess can be simply removed with your thumbnail or a razor.

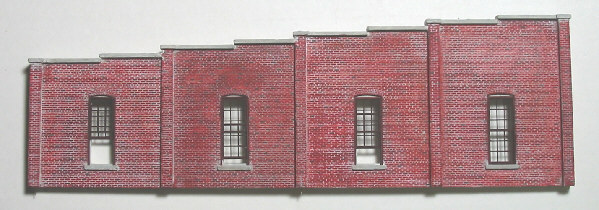

Here are the inspection pit side walls.

NARROW GAUGE RESEARCH CENTER

Here's the research library for the Durango roundhouse.

Some sketch notes.

The laser computer desk.

We're using Corel Draw to run the laser. Looks like the roof panels for

Gunnison'e extended stalls are on the screen.

Durango rounhouse.

Durango rounhouse.

Durango rounhouse.

Next section:

Casting Hydrocal

|  O List Top

O List Top

Crow's How 2

Crow's How 2

Order Crow's

Order Crow's

Contact CCC

Contact CCC