COLORING THE HYDROCAL WALLS

Delta Ceramcoat comes in all colors.

My traditional method for coloring the Hydrocal castings as

explained in my Crow's How 2

section of the web site. These start by sealing the castings (after you have done

all the cutting and fitting) and then use Floquil paints and stains. Since the

stains have been discontinued and my supply is just about out I thought it was

time to seriously look for alternatives. I'd tired acrylics (Polly-Scale) in the

past but always felt the Floquil's looked better. Now that a one ounce bottle

of Floquil acrylic retails for $4.99 and the solvent based paint is fifty cents

less it's time to wake up.

There's nothing special about Floquil. Yeah, they mix up your

favorite railroad colors but we can find the same thing for one tenth, YES, ONE-TENTH

THE PRICE. 99 cents for a 2 ounce bottle in just about any color you want. You'll

find them under several brand names. I chose Delta Ceramcoat but they are inter-mixable

with all the others. Liquitex and Golden both manufacture preimum grades and tube

paint if you want to go that route but there's nothing wrong with the cheap ones

for painting or should I say staining our Hydrocal castings. They are simply an

inexpensive thin gel acrylic paint that should be available at your local crafts

store. I went to Micheal's here in Seattle for mine.

There's a whole rainbow of colors to choose from. Actually it's

not too hard to mix your own. there's even a science to it, starting with the

primary colors of red, yellow and blue. From them you can mix any color you want.

Half red and half yellow gives you orange and so on. Add white and black to make

them lighter or darker. But of course it is easier to buy the colors we need

per-mixed and at a buck per shot- why not?

For the stone we'll start off with a neautral base color.

So look for something that looks like the natural stone, either a light gray, tan

or whatever. Also consider your scenery. What have you chosen there? More than

likely the stones for the building were gathered locally so they should match.

We'll also highlight some of the stones with other colors mimicing those old

Flo-Stains- walnut, teak, a little mahogany.

We'll do the same thing for the brick. Orange, red, brown...

Pick a few of those.

Here are some of the colors I brought home. As mentioned

I bought the primary colors of red, yellow, blue, black and white. I picked up a

green too. I got a couple of greys for the stone. Some tans and light browns. Then

for the brick I got Tuscan red, golden brown and stuff like that. I also brought

home the standard Burnt Umber, Raw Umber, Raw Sienna and Burnt Sienna.

Now we can run some tests!

Color tests on a spare stone wall.

For the stone I started off with a grey. I thinned the

paint with water and simply brushed it on. Note that I did not seal the casting

first. We'll let the acrylic paint do that. Next I painted individual stones at

random with the highlight colors (sandstone, Payne's grey, brown (oxide red) and

toffee brown). I wisely wrote down what I was doing on the back side of the test

panel so I'll have a written record of exactly what I did. With so many colors

it's easy to get mixed up. For instance now, a month later I'm struggling to

remembewr which grey I used on the roundhouse foundation. Quaker Grey? Dolphine

Grey? Or was it Rain Grey? Well, it was one of those. The point is WRITE IT DOWN

and really it's up to you to decide what color you like most.

Start with a base coat of grey. Here I'm testing three different shades.

Highlight ome of the individual stones.

Looking pretty good.

Next step is to see if we can improve the results. The

wall looks okay at this point but I want to see if I can do better. We'll try a

wash of ink stains. Acrylic stain. How about some Builders In Scale Silverwood?

Or mortar mix? I applied some acrylic gloss medium to make the stones shineier.

Let's try some different finishing techniques.

I've wisely written down notes on the back of the test panel.

Test panel A.

Test panel B.

Test panel C.

Here I'm refining the technique that I most like.

I'm looking for something that is quick and easy, not too

complicated. If you were a real artist you could sit down and paint each stone.

But this seems to work. I decided I liked the grey base, a few random stones with

color (don't worry if they aren't precise), a gloss overcoat, then a SilverWood

wash.

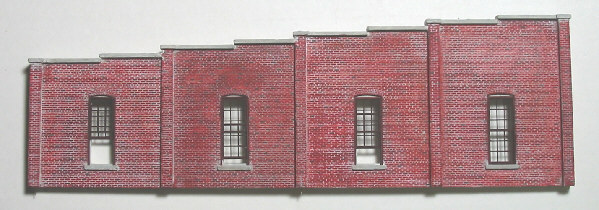

I did similar tests on the brick using various reds and

browns. Burth Sienna was my favorite.

Color tests for brick.

Color tests for brick.

Here's the one I like.

To finish them I used a thin wash of Builders In Scale

mortar mix. Initially I over-applied the mortar mix which is my custom on HO models.

However, after applying it thick to the inside walls I came to my senses and did it

very thinnly to the exterior. It's a light-grey and we don't have to fill in the

mortar lines, just accent them. Mix only a little at a time. Here I'm using a

brush. Then wipe the excess away with a paper towel and polish the surface.

So, let's review the technique:

Squirt a little paint into a mixing cup.

Add some water, be consistant.

Apply to the wall. A little streaking is okay.

Cover the whole wall.

.

side wall.

mixing the mortar

spread it out

blot and polish

finished side wall.

The saw-toothed corbels were a bit of a challange. Easy

does it and do a little at a time. The mortar mix lightens up considerably so keep

an eye on it as you proceed.

Applying mortar to the corbels.

Now, this is not the only way to do it. As I first mentioned

I've always been pleased with Floquil solvent based paints. Other brands will likely

work just as well. You may already have your favorite method down or like that of

another manyfacturer or modeling author. Glenn for instance used the same basic

techniques on his Gunnison roundhouse model but chose to do them darker, capturing

the "Black Canyon of the Gunnison". That's the thing, do what you think is right.

With the cost savings, ease of use, lack of nasty solvents-

All in all I'd say acrylics are the way to go. Though I do not recommend it I also

found cutting the finished castings is possible. More so than with the rock hard

finish of sealing and painting. I had miscalculated the corner pieces of the rear

wall and needed to trim them which I did without cursing. You really want to do the

rough work before painting and finishing.

Next section:

Building the Roof

|  O List Top

O List Top

Crow's How 2

Crow's How 2

Order Crow's

Order Crow's

Contact CCC

Contact CCC